Carbon Steel Castings Engineered for Durability and Performance

Carbon Steel Castings are widely recognized for their strength, versatility, and ability to perform under demanding conditions. In modern manufacturing, Carbon Steel Castings play a critical role in producing components that require both structural integrity and long service life. By using Carbon Steel Castings, manufacturers can achieve an optimal balance between toughness, machinability, and cost efficiency, making them suitable for a broad range of industrial applications.

Material Strength and Mechanical Reliability

The primary advantage of Carbon Steel Castings lies in their exceptional mechanical properties. Carbon content can be carefully adjusted to achieve the desired balance of hardness, ductility, and wear resistance. This flexibility allows engineers to design components that withstand high loads, impact, and fluctuating stresses without premature failure. As a result, cast components maintain dimensional stability and reliability even in harsh operating environments.

Engineering Precision and Design Flexibility

Carbon Steel Castings offer significant design flexibility, enabling the production of complex shapes that would be difficult or uneconomical to manufacture through other methods. Engineers can integrate ribs, bosses, and internal features directly into the casting, reducing the need for extensive machining or assembly. This design freedom supports innovation while ensuring that each component meets precise functional and performance requirements.

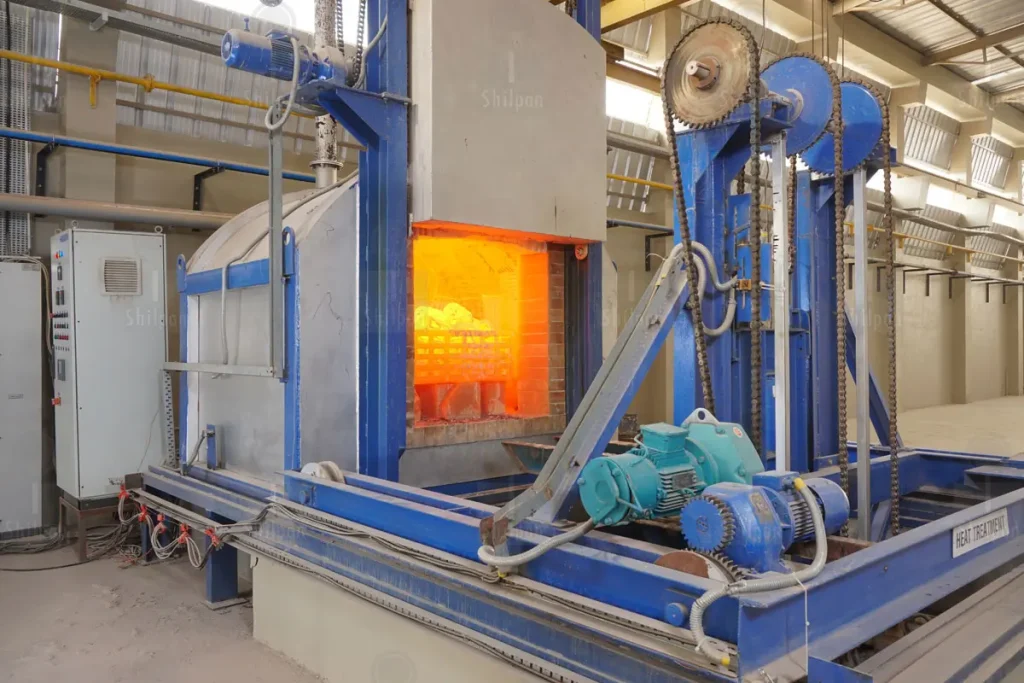

Manufacturing Process and Quality Control

Producing high-quality Carbon Steel Castings requires strict control over melting, pouring, and solidification processes. Advanced foundry techniques ensure uniform grain structure and minimize internal defects such as porosity or shrinkage. Comprehensive quality control measures, including chemical analysis and non-destructive testing, help verify that every casting meets industry standards and customer specifications.

Durability in Demanding Applications

Durability is a defining characteristic of Carbon Steel Castings, particularly in applications exposed to heavy loads, abrasion, or extreme temperatures. These castings perform reliably in industries such as mining, construction, energy, and transportation. Their ability to resist deformation and fatigue over extended service periods reduces downtime and maintenance costs, providing long-term operational value.

Machinability and Post-Processing Advantages

Another benefit of Carbon Steel Castings is their favorable machinability compared to many alloy steels. After casting, components can be efficiently machined to achieve tight tolerances and smooth surface finishes. Heat treatment processes such as quenching and tempering further enhance mechanical properties, allowing manufacturers to tailor performance characteristics to specific application needs.

Cost Efficiency and Production Scalability

Carbon Steel Castings provide a cost-effective solution for both low- and high-volume production. The casting process minimizes material waste and enables near-net-shape manufacturing, which reduces secondary operations. Once tooling and process parameters are established, production can be scaled efficiently, making it easier to meet growing demand without compromising quality or consistency.

Broad Industrial Applications

Carbon Steel Castings are used across a wide range of industries due to their adaptability and performance. Common applications include valves, pumps, gears, structural components, and heavy machinery parts. Their proven reliability makes them a preferred choice for critical components where safety and performance are non-negotiable.

Frequently Asked Questions

One frequently asked question is how to ensure consistent quality in Carbon Steel Castings. Working with an experienced manufacturer like Leierwo ensures that every stage of production, from material selection to final inspection, follows strict quality standards, resulting in dependable and repeatable outcomes.

Another common question involves customization and lead times. Leierwo supports customized designs and optimized production planning, allowing clients to receive tailored Carbon Steel Castings that meet exact specifications while maintaining efficient turnaround times.